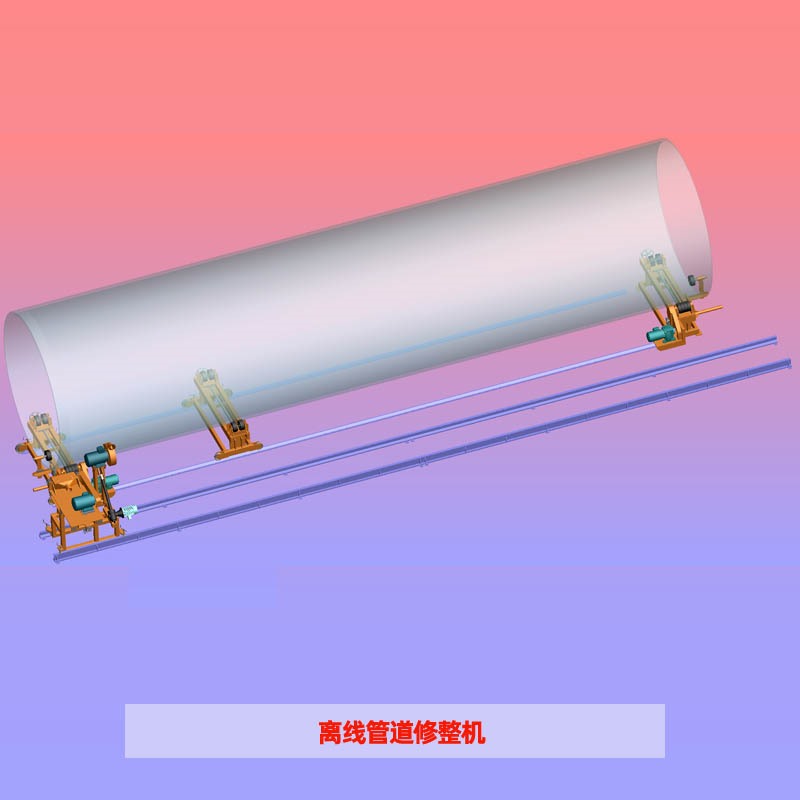

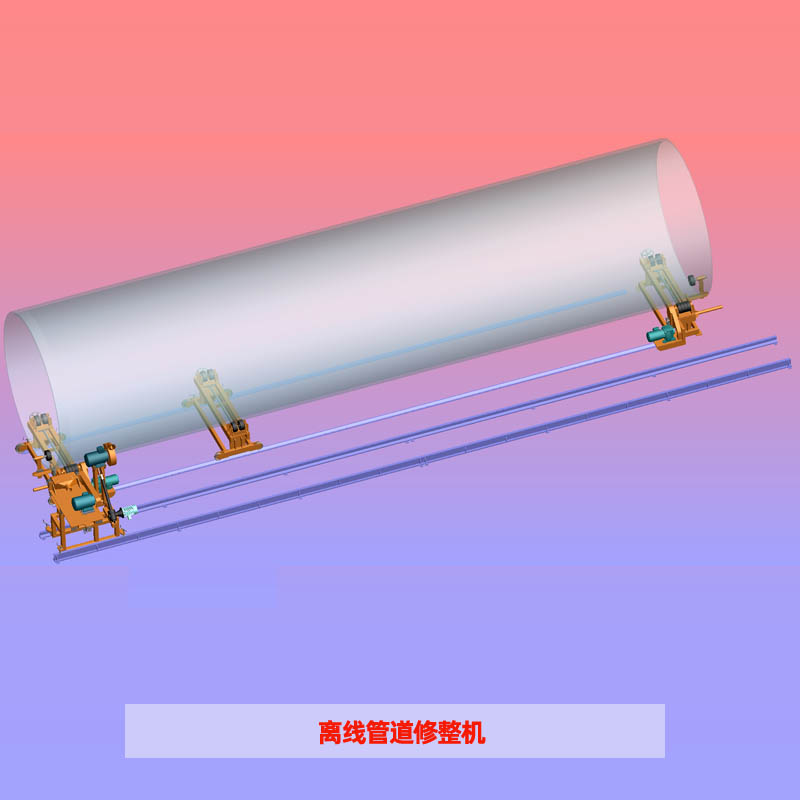

离线管道修整机

ORM离线管道修整机介绍

设备功能、组成及原理:

设备功能

是连续管道生产线上辅助设备,用于短管的离线切割、修整。(主要用于管道测试样品的切割,制作管道附件管道切割,及弥补在线修整的缺陷)

设备组成

主要由支撑小车、修整机磨头、切割头、行走装置、电控系统等机构组成。

工作原理

将待修整、切割的管道放置在驱动托辊、固定托辊上。启动驱动托辊使管道旋转,并调好二端的限位装置。调整好切割磨削头尺寸定位装置,启动切割磨削头对管道进行切割、修整。

Introduction to Offline Pipe Trimming Machine

Equipment function, composition and working principle:

Function--

As an auxiliary equipment in the continuous winding production line, Offline Pipe Trimming Machine is designed for the cutting and grinding of short pipes. (Mostly used for the cutting of testing pipe and pipe accessories and remedying the limitation of online trimming.)

Composition--

It mainly consists of support trolley, grinding head, cutting head, running device and electrical control system.

Working principle--

Lay the pipe for being cut and trimmed onto the driving support rollers and fixed support rollers. Then, start the driving rollers to make pipe rotate and adjust the positioning devices on both ends. After setting the sizing device of cutting and grinding heads, start to cut and grind the pipe.

上一条:连续玻璃钢管道缠绕机

下一条:环向强度测试机

版权所有 Copyright 连云港唯德复合材料设备有限公司 All Right Reserved

©苏ICP备05000891号-1